案例分析 I 2023-12-11

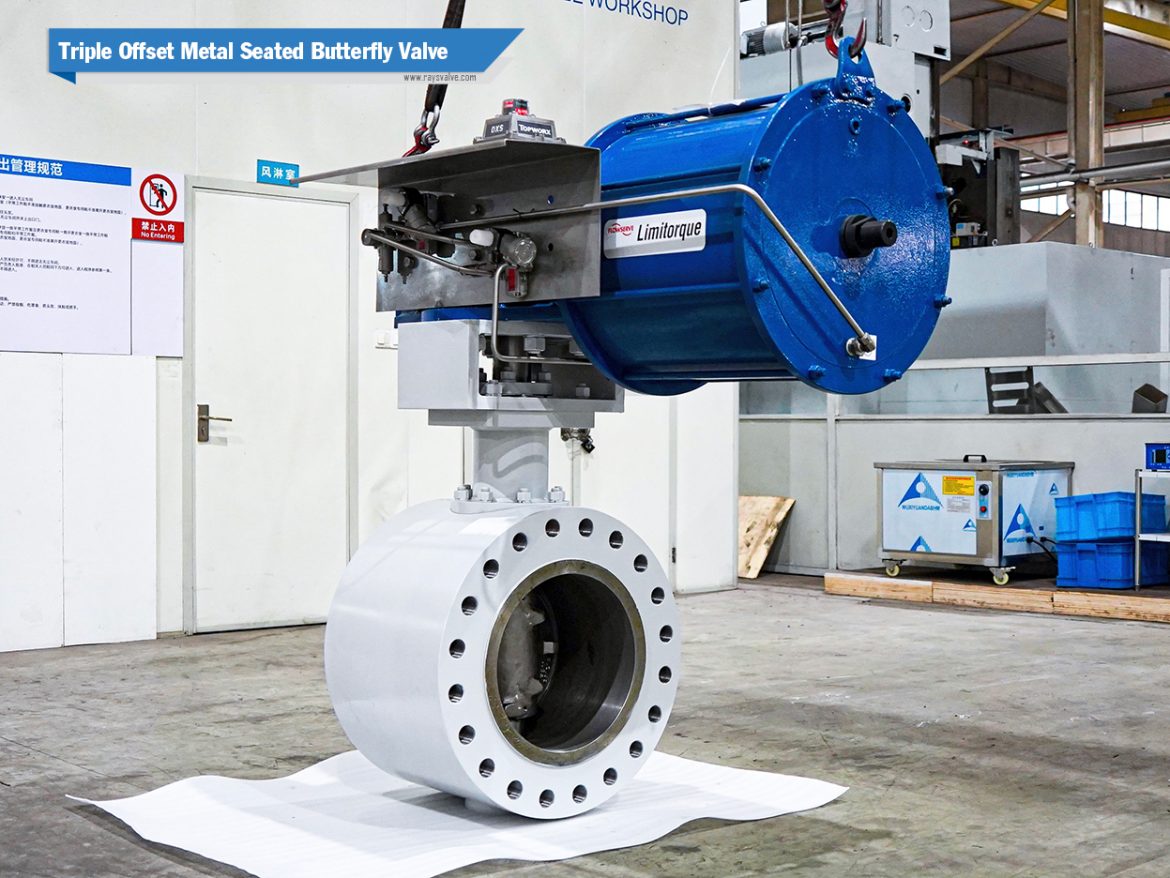

RAYS Triple Offset Metal Seated Butterfly Valve

Triple Offset Metal Seated Butterfly ValveTriple Offset Butterfly Seated Valves are a type of high-performance butterfly valve, also known as triple eccentric metal-seated butterfly valves. These valves are designed with a triple offset structure that provides tight sealing characteristics, making them excellent for high-pressure and high-temperature applications. Technical ParametersProduct Type: Triple Offset Metal Seated Butterfly ValveSize Range: DN50-DN1200 or 2″-48″Pressure Rating: From 150LB to 2500LBOperating Temperature: From -196C to 650CConnection Type:RF, BW, LUG,WaferMaterial: Carbon steel (such as WCB), stainless steel (such as CF8/CF8M), alloys (such as Monel), duplex steel, etc.Suitable Medium:Butterfly Valves are designed to control fluid types such as water, oil, gas, steam, etcOperation Mode: Handle, turbine, gas-hydraulic linkage, electric, pneumatic, electro-hydraulic linkage, etc Product FeaturesGood sealing performance: Due to their eccentric design, when the valve is closed, the disc can tightly fit against the seat, achieving metal-to-metal sealing and minimizing leakage.High temperature and pressure tolerance: Metal sealing components enable triple offset butterfly valves to withstand higher temperatures and pressures, making them more durable than ordinary rubber or PTFE sealed butterfly valves.Longevity and low maintenance costs: Reduced friction means less wear and tear, leading to an extended service life and lower maintenance costs. The three “offsets” implication:First offset: The disc is offset from the shaft axis, which allows for reduced friction between the disc and the seal during opening.Second offset: The shaft axis is offset from the pipe centerline, which further reduces friction and wear between the sealing surfaces.Third offset: The centerline of the sealing surface is offset, often with the disc sealing surface and seat sealing surface being conical. This conical configuration allows for a tighter seal upon closure. Because of these characteristics, triple offset butterfly valves are very popular in critical processes within industries such as oil and gas, chemical, heating, and water treatment.…

Read more